In this blog we explore CC-CV charging from a technical point of view, understand its importance and break down a major misconception in the market around the CC-CV.

Introduction:

Ever wondered why your EV charges quickly at first, then suddenly slows down toward the end? It’s not a bug, it’s how most chargers are designed to work. But surprisingly, that design choice isn’t always the most efficient.

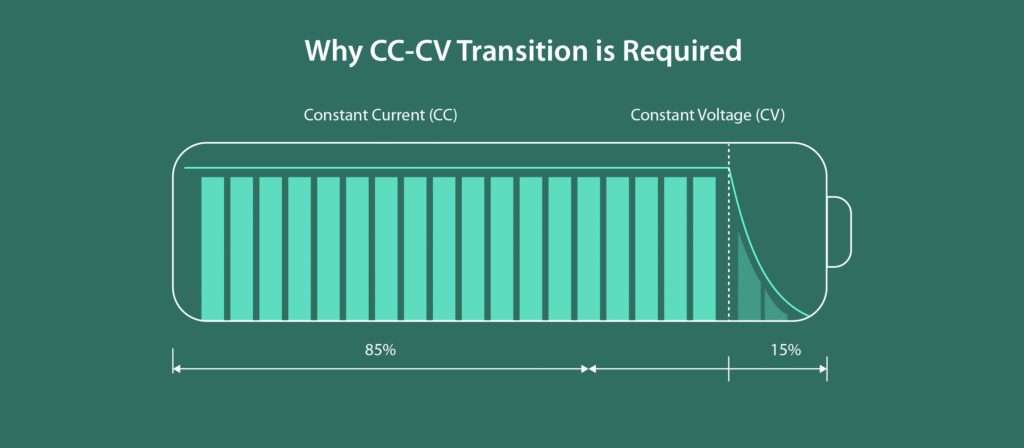

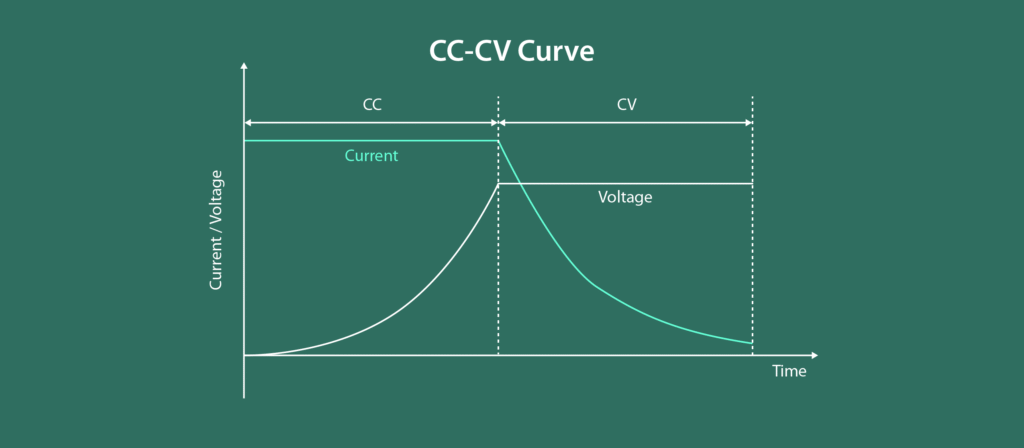

There are various types of charging methods, each of them work towards charging the battery effectively. One of the methods is CC-CV charging wherein the battery charges its significant capacity using the Constant Current (CC) and the remaining portion of it is charged using the Constant Voltage (CV). This transition happens mainly because if we charge 100% battery using the CC, we may see a wrong State of Charge (SOC), overcharging, excessive heat and other problems.

But here’s the catch: most chargers switch to CV too early, sometimes when the battery is only 70–80% full. That early transition leads to longer tail-end charging times, energy losses and reduced overall efficiency – all because of one outdated assumption.

So, at Vecmocon, we ask one simple question: What if that switch could be smarter? What if the battery itself could tell us the right moment to transition?

In this blog, we’ll break down how rethinking that one moment the CC-CV transition can unlock faster, safer, and more intelligent EV charging, and how our technology is leading the way.

Why is CC-CV transition required?

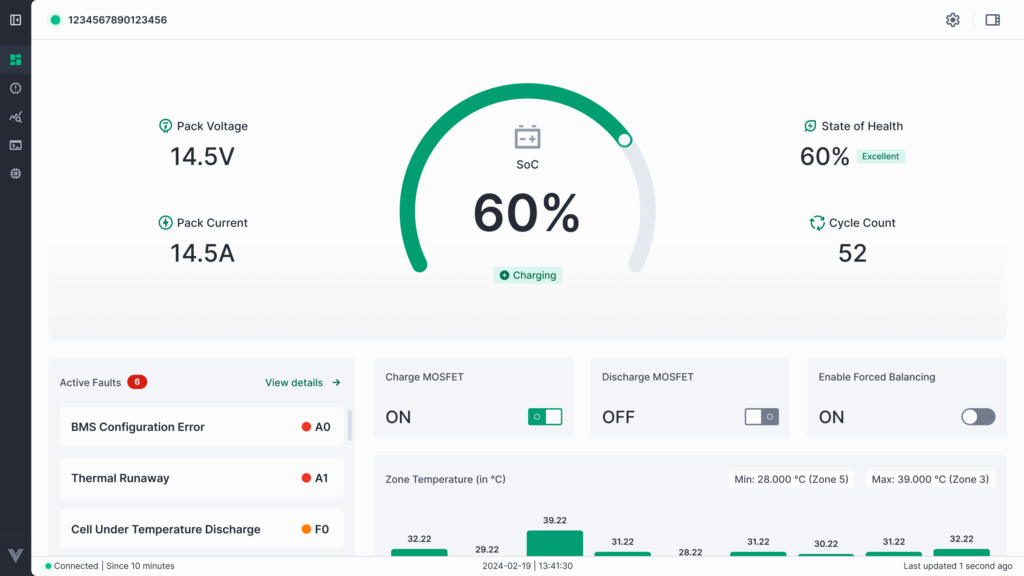

To understand why the CC-CV transition is necessary, we need to look at how a lithium-ion battery behaves during charging and the components inside a Battery Management System (BMS) that manage this process.

To better understand why is CC-CV transition is required, let’s use the analogy of a glass & water –

Think of charging a battery like filling a glass of water. When the glass is empty, you can pour quickly without worrying, as the risk of overflow is minimal. But as the water level rises and nears the top, you slow down the pour and become more careful to avoid water spilling.

This mirrors how CC-CV charging works at the start. When SOC is lower, we charge faster with CC, then as the SOC rises, we shift to CV, a much controlled and slower charging mode.In the Constant Current (CC) phase, the charger delivers a fixed current to the battery pack. This current is usually in the range of 0.5C to 1C(where C is the capacity of the battery in ampere-hour (Ah), depending on the battery specifications. During this phase, the battery voltage steadily increases. The current sensor (typically a Hall effect sensor or a shunt resistor) continuously monitors the charging current, and the microcontroller (MCU) inside the BMS ensures it stays within the safe range.

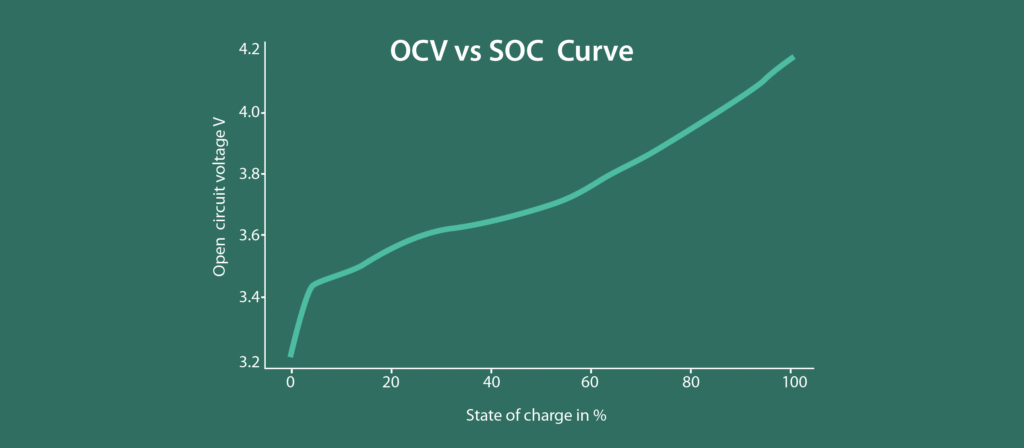

The OCV–SOC curve maps a battery’s open-circuit voltage to its state of charge, and in a CCCV charging profile it determines the precise SOC at which charging shifts from the constant-current (CC) phase to the constant-voltage (CV) phase for optimal performance and safety.

As the battery voltage approaches its upper threshold, usually around 3.4V per cell for LFP chemistry. The total battery pack voltage is sensed by the charger, and it initiates the transition to CV. At this point, continuing to charge at the same current could cause the voltage to rise above safe limits. This can lead to dangerous effects like lithium plating, excessive heat, or cell degradation.

To prevent this, the charger switches to the Constant Voltage (CV) phase. Here, the voltage is held steady at the maximum limit, and the current begins to decrease by following Ohm’s Law, as the battery approaches full charge.

How CC-CV takes place inside the battery:

Now that we know why the CC-CV transition is important, let’s look at how it actually happens inside the battery both from the electrochemical side and from the control system’s perspective.

When you start charging a lithium-ion battery, it enters the Constant Current (CC) phase. During this time, lithium ions begin moving from the cathode (positive electrode) to the anode (negative electrode) through the electrolyte.

Inside the battery, this increasing voltage corresponds to more lithium ions being stored in the anode. The BMS continuously monitors each cell’s voltage using cell monitoring ICs, while the microcontroller checks for safety and balance. If one cell starts charging faster than the others, balancing circuits are triggered to keep the pack uniform.

As the battery nears full charge, the cell voltage approaches its peak, usually around 3.5 volts per cell(for LFP), depending on the battery chemistry. This is where the transition to the Constant Voltage (CV) phase happens.

In the CV phase, the charger stops increasing voltage and holds it steady at the peak level of 3.5 volts per cell. The battery is now almost full, and its voltage starts increasing. This makes it harder for current to flow in. As a result, the charging current naturally begins to taper down. This slower current allows the remaining lithium ions to safely intercalate into the anode without stressing the battery. Due to the lower current in CV mode, it takes longer to charge.

Throughout this phase, the BMS uses current sensors to track how fast the current is falling. Once it drops below a certain limit typically around 0.05C the battery is considered fully charged. If any cell crosses the safe voltage or temperature range during this time, the charge control MOSFETs will isolate the pack to prevent damage.

This entire transition is carefully managed by the BMS firmware, combining real-time data from voltage sense lines, current sensors, temperature sensors, and MOSFET switching circuits.

How VECMOCON is breaking this misconception:

The market has standardized this transition timing i.e. around 70 to 80% of the SOC which is not correct for all the batteries in the market.

In real-world EV charging scenarios, the voltage measured at the battery terminals can be significantly affected by the voltage drop across the DC charging cable — especially at higher charging currents. This drop is governed by Ohm’s Law (V = I × R), where even a small resistance in the cable can lead to substantial losses at high current levels. As a result, the charger may prematurely reach the target voltage (e.g., 4.2 V per cell) not at the actual battery terminals, but at the charger’s end of the cable. This leads the Battery Management System (BMS) to falsely detect that the battery has reached its upper charging threshold and shift into the Constant Voltage (CV) phase earlier than necessary. This early transition not only extends the overall charging time but can also lead to incomplete battery utilization and reduced energy throughput.

Hence, the timing to switch to CV purely depends upon the battery chemistry and SOH, having a generalized range or terminal voltage measured by a Charger can sometimes be too late or too early. To understand the consequences of switching to CV inaccurately, let’s see the comparison of 2 conditions.

| Scenario | Switching to CV Too Early | Switching to CV Too Late |

| Charging Time | Charging takes significantly longer due to extended CV phase and slow current tapering. | May appear faster at first but eventually slows down as voltage overshoots must be corrected. |

| Energy Efficiency | Lower overall efficiency, more time spent in low-current trickle charging with higher relative losses. | Can create sudden current surges when voltage exceeds safe limits, causing inefficiencies in voltage regulation. |

| Thermal Stress | Lower immediate thermal stress but longer sustained heat over time. | Higher peak thermal stress cells heat up quickly and require active cooling to avoid damage. |

| Perceived SoC Accuracy | Can underreporting usable capacity battery may appear to “charge slowly” after 80%. | Can overreport SoC, temporarily the voltage readings can falsely suggest higher charge state. |

Despite these drawbacks, early CV switching has become an accepted practice mainly because it avoids complex control challenges and safety. As a result, many customers and even OEMs have come to assume this is the “right way” to charge. In reality, it’s a shortcut, not a best practice.

How VECMOCON chargers switch to CV more accurately

At Vecmocon, we follow the same CC-CV principle but with much more intelligence behind the switch. Our in-house smart control algorithm dynamically manages the transition point based on real-time data from the battery, instead of using a fixed SoC threshold.

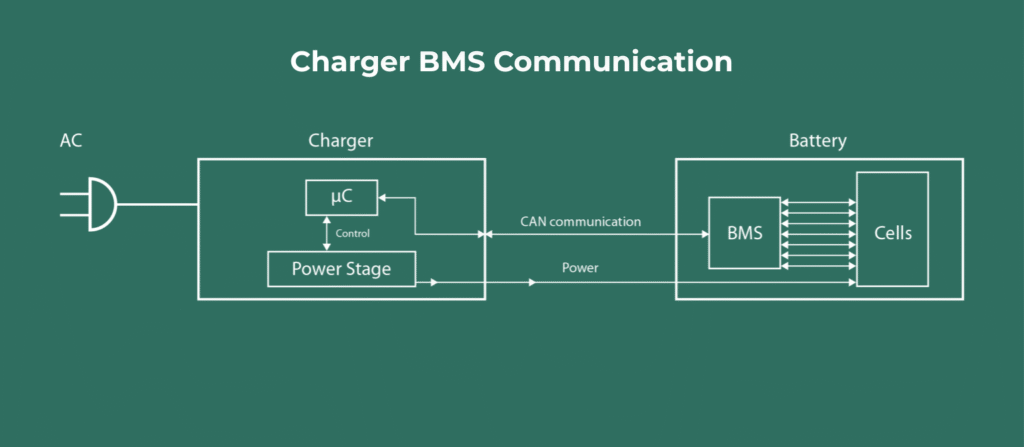

In a CCCV charging system, CAN communication plays a vital role in ensuring the accurate and timely transition from constant current (CC) to constant voltage (CV) mode by enabling real-time SOC monitoring from the Battery Management System (BMS). The BMS continuously calculates SOC using algorithms based on the OCV–SOC curve, coulomb counting, and temperature compensation, then transmits this data over the CAN bus to the charger. By receiving and interpreting this SOC data instantly, the charger can precisely determine when the battery has reached the SOC threshold for switching to CV mode, ensuring optimal charging efficiency, battery safety, and longevity while avoiding overcharging or thermal stress.

WHAT MAKES VECMOCON SYNONYMOUS WITH ACCURACY:

- We extend the CC phase much closer to the true full charge

- We switch to CV more accurately, leading to controlled and better charging retention.

- We continuously monitor cell-level voltage, current, SoC, temperature, and SOH

This allows us to make the CC-CV transition not just safe, but efficient and adaptive, tailored to the actual condition of the battery, not a one-size-fits-all setting.

Customer Perception vs. Engineering Reality

There’s a widespread belief in the market that switching to CV early is safer or better for the battery. But this is more of an industry habit than a scientifically grounded practice. In many cases, it’s just a result of using simpler charging logic.

In contrast, our chargers:

- Charge faster

- Consume less energy

- Are more protective of battery health over time