The Internet of Things (IOT) has brought a revolutionary impact on electric vehicles and the mobility sector as a whole that ICE vehicles could never have, especially in the 2 and 3-wheeler sector. Why so? Due to the electrification of vehicles. Since a majority of the parts, like batteries, motor controller, VCU, etc, are all controlled by silicon chips, enabling them to connect with the IOT device.

But why are we calling it revolutionary? Well, because now it has enabled a lot of business use cases for an automobile and brought a lot of opportunities to streamline and safeguard those use cases.

In this blog, we will elaborate on the value that IoT brings to the table, how people are building various businesses with this technology, and explore how it works and its associated challenges.

Role of IOT in an EV and how it works:

If we see it mechanically, it’s a little device that sits inside the vehicle (mostly on top of the battery pack) to do the following tasks:

- Send vehicle-level data to the cloud

- Store critical vehicle data if cloud connectivity is not possible

- Enable GPS connectivity

- Real-time decision making or Edge computing

Here’s how it works,

Microcontroller unit (MCU): It’s the most fundamental part of an IOT device.

It acts as the brain of the IoT device. It receives signals from various sensors, processes the data, and determines the actions to take or the information to send to the cloud. The MCU also executes the firmware, the embedded software that defines how the IOT device behaves in different conditions.

Communication module: It handles how the device connects to external networks. This could include GSM, 4G LTE, or even 5G connectivity. Through this, the IoT device sends live vehicle data such as speed, battery health, and motor status to the cloud servers. It also receives commands or software updates remotely, allowing two-way communication between the vehicle and backend systems.

GPS module: This continuously tracks the vehicle’s location, speed, angle, axis, etc., enabling fleet operators or OEMs to monitor vehicle movement in real-time. It can also support functions like geofencing, route optimisation, or theft prevention.

CAN communication interface: the link between the IoT device and the vehicle’s other electronic systems. Through the Controller Area Network (CAN) bus, the IOT device exchanges information with the BMS, motor controller, charger, and dashboard cluster. This enables it to collect data, such as battery voltage, current, temperature, or fault codes, directly from each subsystem.

Power management circuit, which ensures the IoT device gets a stable and noise-free power supply, is usually derived from the vehicle’s low-voltage auxiliary line. It manages startup sequences, protects against voltage spikes, and maintains energy efficiency.

Together, these components form a smart and self-sufficient system. When a sensor detects a change, a rise in battery temperature, the MCU processes this data and decides whether to alert the cloud or take immediate action locally through edge computing. The communication module then sends the relevant information to the backend, where analytics platforms can interpret trends or flag anomalies.

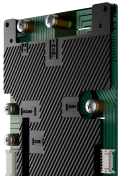

Vecmocon’s IOT device – VIM

At Vecmocon, we built the Vehicle Intelligence Module (VIM) not as just another GPS tracker, but as the central nervous system of an electric vehicle. It is a fully automotive-grade IoT platform designed to give OEMs, fleets, and service teams complete, real-time visibility and control over their EVs.

Unlike generic telematics devices that only push basic location data, the VIM is engineered ground-up for deep EV integration. It communicates directly with critical subsystems like the BMS, motor controller, charger, and VCU over high-speed CAN, enabling insights that go far beyond simple tracking.

What makes Vecmocon’s VIM different?

- EV-First Architecture – Built to read 200+ real-time parameters including cell-level battery data, fault codes, thermal status, charging behavior, and drivetrain efficiency.

- Smart Edge Processing – Instead of dumping raw data to the cloud, VIM processes part of the data locally, enabling faster decisions and reduced cloud load.

- Cloud + OTA Ready – Fully compatible with Vecmocon’s cloud stack and supports secure firmware-over-the-air updates to both the VIM and other ECUs like BMS/VCU.

- Industry-Grade Reliability – Designed as per automotive EMC/EMI standards, IP67 waterproofing, and -20°C to +70°C thermal tolerance.

- Dual Power & Backup – Works with vehicle power but also includes an inbuilt lithium backup so critical functions like theft alerts and GPS tracking stay active even when the vehicle is switched off.

- Plug-and-Scale Deployment – Supports 2W, 3W, and LCV platforms with the same firmware architecture, making it easy for OEMs to scale across models.

The result? A single IoT system that acts as—

- A real-time diagnostic tool for OEMs

- A fleet-intelligence engine for operators

- A performance and safety shield for end customers

- A data feedback loop for next-gen product development

In short, VIM is not an addon — it is the intelligence layer of an EV.

Business use cases of VIM:

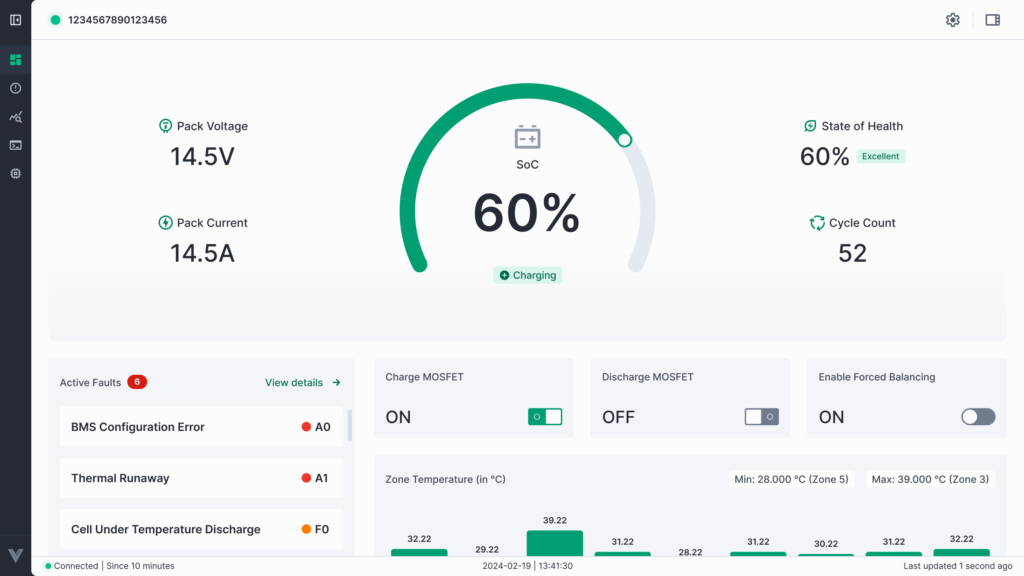

The Vehicle Intelligence Module (VIM) turns a vehicle into a connected, data-driven system. By continuously sensing, analysing, and transmitting data, it unlocks multiple business and operational benefits.

- Real-time asset tracking: The biggest challenge for any fleet owner is asset security, where devices like VIM play a vital role in identifying the location of the vehicle, geo-fencing, and tracking asset history.

Such features are mostly used by Vehicle or battery leasing companies to keep track of their asset, do user profiling and mitigate risks.

- Remote diagnostics and updates: OEMs can remotely access diagnostics, identify faults, and deploy over-the-air updates or implement FOTA. It cuts service costs and time, while 2 and 3 wheeler ICE vehicles still depend on physical workshops for every calibration or fix.

- Data-driven decision making: This particular feature is mostly used by financing companies to identify the cost of financing any particular vehicle or to identify the risk of financing any particular person. Based on their driving pattern and vehicle performance. To enable the above, the data from VIM helps a lot.

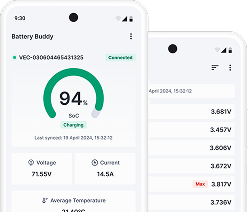

- Smarter user experience

For riders, VIMs enable app-based visibility into battery health, charging status, and performance insights. - Predictive maintenance

VIMs track key parameters like battery temperature, voltage, and motor current to predict issues before they occur. This reduces downtime and increases vehicle life, unlike ICE vehicles that rely on periodic, reactive servicing.

In essence, the VIM is what makes EVs intelligent machines capable of learning, adapting, and delivering value far beyond traditional engines.

Challenges with IOT and how Vecmocon is solving them

IoT is redefining how EVs connect, operate, and evolve, but it also brings challenges that demand deep engineering precision. At Vecmocon, we’ve built our IoT ecosystem to overcome these real-world constraints without compromising reliability or performance.

1. Connectivity and Network Reliability

One of the biggest real-world challenges for any IoT system in electric vehicles is unreliable network availability. EVs in India frequently operate in areas with weak cellular coverage such as basements, hilly terrain, rural delivery routes, dense urban clusters, underground parking, industrial zones, and metal-shielded warehouses. In such conditions, both GSM/4G connectivity and GPS positioning can drop, leading to gaps in data transmission and loss of real-time visibility.

Traditional telematics systems fail under these circumstances because they depend on uninterrupted cloud connectivity. Vecmocon’s VIM is designed to avoid this dependency through a store-and-forward architecture.

It locally stores all critical vehicle data — including GPS position, battery health, fault logs, trip history, and charging events — in non-volatile memory. When network connectivity is restored, the VIM automatically syncs all pending data to the cloud in the correct chronological order. This ensures that no information is lost, even if the vehicle has been offline for several hours or days.

In addition to data buffering, the VIM applies intelligent prioritization. High-severity events such as thermal runaways, over-current faults, or unauthorized vehicle movement are tagged as priority data and uploaded first during reconnection. Lower priority logs are compressed to optimize bandwidth during sync. The device can also function in a completely offline mode during workshop servicing, with logs retrievable through CAN or Bluetooth, allowing diagnostics even without cloud access.

This architecture ensures that connected intelligence continues to operate even in low-signal environments, and that fleet operators, OEMs, and service teams never face blind spots in vehicle history or performance analytics.

In summary, Vecmocon’s VIM eliminates the weakest link in EV connectivity by ensuring:

- No data loss, even during extended network outages

- Complete traceability for warranty, service, and fleet analytics

- Reliable vehicle monitoring without dependence on continuous GSM availability

- Edge-based decision-making and logging, not cloud-dependent execution

This turns IoT from a “works only when connected” feature into a reliable, fault-tolerant system fit for real-world Indian EV operations.

- Power Consumption and Efficiency

IoT devices draw from the vehicle’s limited battery. Vecmocon’s power-saving mode reduces power draw exponentially as SOC drops. A small backup battery also powers essential IoT functions without affecting vehicle range. - Data Volume and Bandwidth Management

Continuous streaming of GPS, BMS, and motor data consumes heavy bandwidth. Vecmocon uses edge computing to process data locally and send only key insights to the cloud saving bandwidth and enabling faster analytics. - Security and Data Privacy

Sensitive data, such as location and performance metrics, requires airtight protection. Vecmocon ensures this through secure boot, TLS encryption, and PKI authentication, keeping every transmission safe and verified. - Environmental and Mechanical Robustness

IoT devices are exposed to vibration, heat, and moisture. Vecmocon designs with automotive-grade hardware, IP67 enclosures, and EMI shielding ensuring consistent performance in all environments. - Firmware Updates and Maintenance

Vecmocon’s secure FOTA system allows remote firmware updates with rollback and digital verification, ensuring safe and consistent upgrades across the fleet. - Scalability and Cloud Infrastructure

Managing millions of connected EVs demands scalability. Vecmocon leverages distributed IoT architecture and cloud platforms like AWS IoT and Azure IoT Hub to handle massive data loads efficiently.

Conclusion: The Connected Future of Mobility

The Internet of Things has become the invisible engine driving the next evolution of electric mobility. It has turned EVs from being just clean machines into intelligent ecosystems capable of sensing, learning, and improving themselves in real time. From predictive maintenance and remote diagnostics to data-driven design and fleet optimisation, IoT has unlocked possibilities the ICE world could never imagine.

But this transformation isn’t without challenges. Connectivity gaps, energy constraints, and data overload continue to test the boundaries of what IoT can achieve on wheels. And that’s where Vecmocon stands out by engineering hardware, software, and cloud infrastructure that make connected mobility both practical and scalable.

As EV adoption accelerates, the vehicles of the future won’t just move people they’ll move information, intelligence, and insight. And with solutions like Vecmocon’s VIM at the core, that future isn’t far away. It’s already on the road.